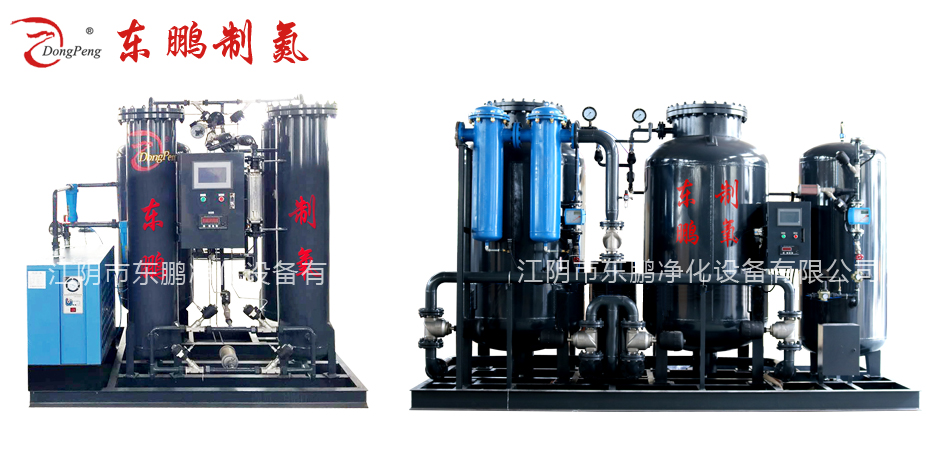

PSA Oxygen Generator

Process principle:

PSA oxygen plant uses clean compressed air as raw material, zeolite molecular sieve as adsorbent, and uses PSA principle to obtain oxygen at room temperature. According to the difference of the adsorption amount of oxygen and nitrogen in the air and the diffusion rate of oxygen and nitrogen in the zeolite, the opening and closing of the pneumatic valve is controlled by the programmable controller to realize the process of pressure adsorption and pressure reduction desorption, complete the separation of oxygen and nitrogen, and obtain the oxygen of required purity.

Technical features:

DPO series oxygen generator (the oxygen purity is generally 90% - 93%, and the pressure is 0.1-0.4mpa) is our company's experience in professional research and development of PSA nitrogen generator for many years. Combined with the technical characteristics of PSA oxygen generator in Germany, the equipment has the advantages of low operating cost, high degree of automation, stable oxygen purity flow, simple operation, etc.

Technical parameter table:

| Model |

The oxygen flow rate

Nm³/h

|

The oxygen purity

(%)

|

Overall dimension(m)

L×W×H

|

| DPO-3 | 3 | 90-95 | 1200×1200×1800 |

| DPO-5 | 5 | 90-95 | 1200×1200×2000 |

| DPO-10 | 10 | 90-95 | 1600×1500×2150 |

| DPO-20 | 20 | 90-95 | 1800×1700×2550 |

| DPO-30 | 30 | 90-95 | 1900×1700×2600 |

| DPO-50 | 50 | 90-95 | 2100×2000×2750 |

| DPO-100 | 100 | 90-95 | 5500×1550×3200 |

| DPO-150 | 150 | 90-95 | 6000×1800×3500 |

| DPO-200 | 200 | 90-95 | 6600×2000×3700 |

Prev

Next

Back